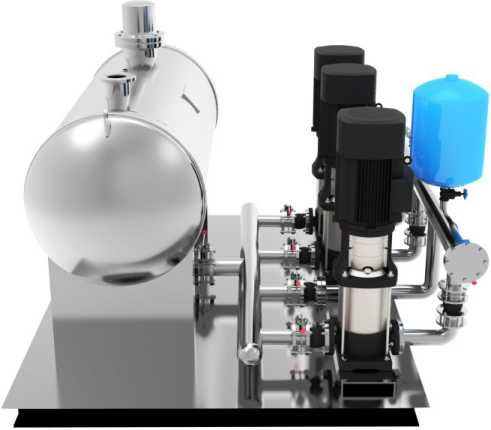

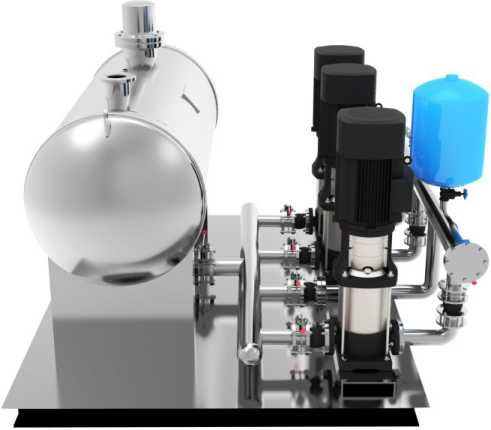

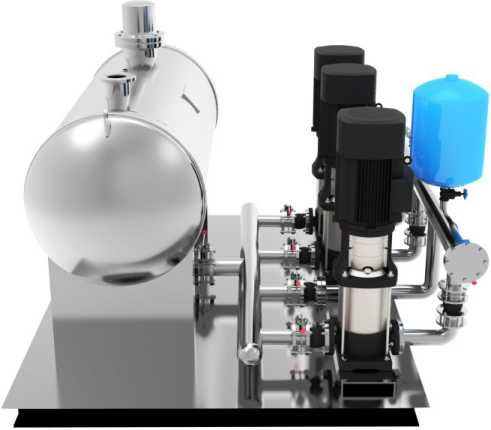

Products Details

The tank-type pipe network stacking (no negative pressure) variable frequency water supply equipment is a water supply equipment composed of a stainless steel steady flow tank, a pump set and a control cabinet. Connect the system equipment in series where the pressure of the municipal water pipe network is insufficient. The equipment detects the outlet pressure through a pressure sensor or a remote pressure gauge, compares the detected value with the set value, and calculates it on the basis of the original pressure of the municipal water pipe network. The pressure value that needs to be increased, determine the number of pumps put into operation and the output frequency of the inverter (reactive to the speed of the motor and the water pump) in order to conform to the water curve to achieve constant pressure, and the tank-type pipe network is superimposed (no negative pressure). It utilizes the original pressure of the municipal water pipe network effectively, does not generate negative pressure on the municipal pipe network, replaces the old-fashioned pool with a stainless steel steady flow tank, reduces the secondary pollution of water, and is a new generation of energy-saving products in the field of water supply. Features •No negative pressure The equipment is equipped with an air pre-pressure self-balancing system, which can prevent and eliminate the negative pressure generated by the operation of the equipment. The equipment is equipped with a negative pressure suppressor, which has a perfect negative pressure detection control cabinet function, which can monitor and warn in time before the negative pressure is generated and eliminate it. It is by no means passive elimination after the negative pressure is generated. • Borrowing (or stacking) The equipment uses the pressure of the municipal water pipe network during operation, and pressurizes it on this basis. Compared with absorbing water from ordinary reservoirs, it can reduce the number of pumps or reduce the number of relays during operation to achieve the purpose of energy saving. • maintain constant pressure The equipment detects the outlet pressure in real time through a pressure sensor or a remote pressure gauge, and compares the detected value with the set value to determine the number of motors and pumps put in and the output frequency of the inverter (reacted to the speed of the motors and pumps) to achieve constant pressure water supply. the goal of. • High degree of automation The system can realize automatic control, with manual/automatic switching, timing rotation of main and auxiliary pumps, pressure adjustment, constant voltage, high and low voltage protection, phase loss protection, leakage protection, overload protection, overheating protection, water shortage protection, no water stop, Instantaneous trip protection and other functions. In addition, the man-machine interface can be configured according to user requirements, and the visual remote adjustment, monitoring and maintenance can be realized. • Hygiene The overflow parts are made of food-grade materials such as stainless steel, which conform to the international water-wading hygiene standards. • save on investment The system has no civil water storage facilities such as reservoirs, which saves floor space and reduces building load, thus greatly reducing investment costs. • Energy saving operating costs The system ensures the constant pressure of the pipeline by adjusting the number of input units and operating speed according to the change of water consumption. When the water consumption is large, high power can be input, and when the water consumption is small, the input power is small. When the water consumption is small (such as at night), the system is supplied with water by a low-power pump with variable frequency speed regulation and constant pressure. The system has been operating at the high efficiency point. Thus greatly reducing operating costs. It can save more than 60% of energy. If the municipal pipe network has a certain pressure, it only needs to be supplemented on the basis of the municipal pressure during operation. The same effect is achieved with less power drawn from the grid than with conventional water supply equipment with a reservoir. The energy saving efficiency is very significant. The automatic operation of the system does not require special personnel to be on duty; and because there are no civil water storage facilities such as cisterns, and no water quality treatment equipment, regular cleaning and disinfection work is avoided. Therefore, the operating cost is further reduced. • Install The equipment is assembled as a whole. When installing, it is only necessary to fix the common base, connect the main water inlet pipe and the main water outlet pipe, and the installation of the equipment is completed. Application Offices: such as hospitals, schools, gymnasiums, golf courses, airports, etc. Buildings: such as hotels, office buildings, department stores, large saunas, etc. Irrigation: such as parks, playgrounds, orchards, farms, etc. Industry: such as manufacturing, washing equipment, food industry, factories, etc. Others: renovation of pools and other forms of water supply

Centrifugal Vacuum Pump,

12v Diaphragm Water Pump,

1.5 Hp Sand Filter Pump For Above Ground Pool,

Mag Drive Centrifugal Pump,

Negative Pressure Pump,

Heavy Duty Slurry Pump,

Slurry Vacuum Pump,

Industrial Slurry Pumps,

Centrifugal Jet Pump,

Mining Slurry Pump,