The material of the main parts of the pump: Inlet and outlet section: ZG230-450 Middle section: ZG230-450 Guide vane: QT450 Impeller: QT450 Spindle: 40Cr Sealing ring: QT450 Bushing: HT250 Balance plate: ZG2Cr13 Gimbal: Tin bronze Pump installation steps: 1.1 Preparations 1.1.1 Before assembly, all pump parts, especially the mating finishing surfaces, must be thoroughly cleaned. 1.1.2 Count all the parts, and classify and number the parts according to the assembly order. 1.2 Assembly of pump parts 1.2.1 Pay attention to install the sealing ring in the middle section to prevent it from falling off. 1.2.2 Pay attention to the guide vane anti-rotation pin. 1.2.3 Tighten the nut of the pump body through the rod symmetrically to maintain a proper tightening force. If it is too loose, it will cause leakage of the joint surface of the middle section. If it is too tight, it will cause deformation of the stator parts. Tighten the threaded rod symmetrically. 1.2.4 After the threaded rod is basically tightened, use a dial indicator to find out that the front and rear sections are not parallel. 1.3 Measure the total string volume of the rotor, which should meet the requirements of the drawing. 1.4 Install the front cover and low pressure end cover bearing and lower shoe, and lift the shaft to the center position. 1.5 Use a special lifting tool and a dial gauge to check the runout of the end face of the balance sleeve, which should meet the requirements of the general assembly drawing. 1.6 Assemble the rotor parts and tighten the lock nut. The measured string quantity after the balance plate is installed shall meet the requirements of the general assembly drawing. 1.7 Install the head cover, tail cover, bearing body and the top of the bearing pad and the clearance on both sides, which should meet the specified value of the bearing pad quality requirements. 1.8 Adjust the center of the bearing bush on both sides, and lock the adjusting nut after adjustment. 1.9 Assembling the thrust bearing 1.9.1 For the assembly of the thrust bearing components, scrape and grind the black pads according to the requirements of the bearing components, and the thrust pads should rotate flexibly during assembly. 1.9.2 After the thrust bearing is installed, the axial gap between the balance disc and the balance sleeve should be 0.04~0.08mm according to the requirements of the general assembly drawing, and the adjustment of the gap is realized by the adjusting ring. 1.9.3 After adjusting the clearance, install the thrust bearing and thrust plate, and lock the lock nut. The pump body and the pump cover constitute the working chamber of the impeller. The inlet and outlet flanges are provided with pipe screw holes for installing vacuum gauges and pressure gauges, and the lower part of the pump body is provided with pipe screw holes for discharging residual water. The impeller is single-suction closed type. A balance disc is set to balance most of the axial force. At the same time, a thrust bearing is provided to bear a small part of the axial thrust that may remain. The arrangement of the bearing keeps the shaft in a stable pulling rod state. The impeller must be strictly checked for static balance before assembly to ensure smooth operation. The pump shaft is supported by two babbitt alloy sliding bearings, which are installed in the bearing body in the pump suspension and lubricated with thin oil. There is a sealing ring on the pump body, which can improve the volumetric efficiency of the pump. On the other hand, it can also prevent high-pressure water from flowing back into the suction chamber, disturbing the water inlet flow field, and ensuring the suction performance of the pump. The shaft seal is generally a soft packing seal. When the pump is working, a small amount of medium can be introduced to the stuffing box, and cooling and lubricating water can also be externally connected to play the role of water seal and cooling and lubrication. According to the user's needs, the packing seal can be changed to a mechanical seal. 1.9.4 Adjust the clearance between the thrust bearing seat and the push plate by the cushion to ensure the clearance requirements of the thrust bearing in the assembly drawing.

The material of the main parts of the pump: Inlet and outlet section: ZG230-450 Middle section: ZG230-450 Guide vane: QT450 Impeller: QT450 Spindle: 40Cr Sealing ring: QT450 Bushing: HT250 Balance plate: ZG2Cr13 Gimbal: Tin bronze Pump installation steps: 1.1 Preparations 1.1.1 Before assembly, all pump parts, especially the mating finishing surfaces, must be thoroughly cleaned. 1.1.2 Count all the parts, and classify and number the parts according to the assembly order. 1.2 Assembly of pump parts 1.2.1 Pay attention to install the sealing ring in the middle section to prevent it from falling off. 1.2.2 Pay attention to the guide vane anti-rotation pin. 1.2.3 Tighten the nut of the pump body through the rod symmetrically to maintain a proper tightening force. If it is too loose, it will cause leakage of the joint surface of the middle section. If it is too tight, it will cause deformation of the stator parts. Tighten the threaded rod symmetrically. 1.2.4 After the threaded rod is basically tightened, use a dial indicator to find out that the front and rear sections are not parallel. 1.3 Measure the total string volume of the rotor, which should meet the requirements of the drawing. 1.4 Install the front cover and low pressure end cover bearing and lower shoe, and lift the shaft to the center position. 1.5 Use a special lifting tool and a dial gauge to check the runout of the end face of the balance sleeve, which should meet the requirements of the general assembly drawing. 1.6 Assemble the rotor parts and tighten the lock nut. The measured string quantity after the balance plate is installed shall meet the requirements of the general assembly drawing. 1.7 Install the head cover, tail cover, bearing body and the top of the bearing pad and the clearance on both sides, which should meet the specified value of the bearing pad quality requirements. 1.8 Adjust the center of the bearing bush on both sides, and lock the adjusting nut after adjustment. 1.9 Assembling the thrust bearing 1.9.1 For the assembly of the thrust bearing components, scrape and grind the black pads according to the requirements of the bearing components, and the thrust pads should rotate flexibly during assembly. 1.9.2 After the thrust bearing is installed, the axial gap between the balance disc and the balance sleeve should be 0.04~0.08mm according to the requirements of the general assembly drawing, and the adjustment of the gap is realized by the adjusting ring. 1.9.3 After adjusting the clearance, install the thrust bearing and thrust plate, and lock the lock nut. The pump body and the pump cover constitute the working chamber of the impeller. The inlet and outlet flanges are provided with pipe screw holes for installing vacuum gauges and pressure gauges, and the lower part of the pump body is provided with pipe screw holes for discharging residual water. The impeller is single-suction closed type. A balance disc is set to balance most of the axial force. At the same time, a thrust bearing is provided to bear a small part of the axial thrust that may remain. The arrangement of the bearing keeps the shaft in a stable pulling rod state. The impeller must be strictly checked for static balance before assembly to ensure smooth operation. The pump shaft is supported by two babbitt alloy sliding bearings, which are installed in the bearing body in the pump suspension and lubricated with thin oil. There is a sealing ring on the pump body, which can improve the volumetric efficiency of the pump. On the other hand, it can also prevent high-pressure water from flowing back into the suction chamber, disturbing the water inlet flow field, and ensuring the suction performance of the pump. The shaft seal is generally a soft packing seal. When the pump is working, a small amount of medium can be introduced to the stuffing box, and cooling and lubricating water can also be externally connected to play the role of water seal and cooling and lubrication. According to the user's needs, the packing seal can be changed to a mechanical seal. 1.9.4 Adjust the clearance between the thrust bearing seat and the push plate by the cushion to ensure the clearance requirements of the thrust bearing in the assembly drawing. DG type multi-stage boiler feed pump

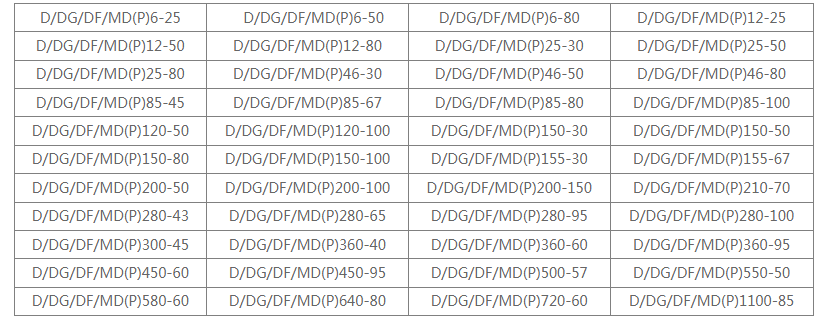

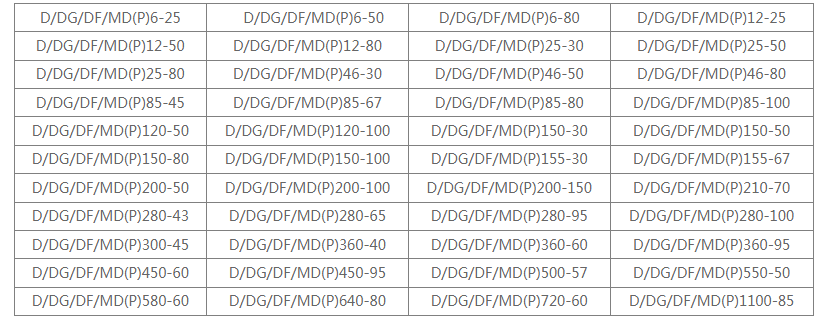

Flow: 3.7-1350m³/h Head: 49-1800m Efficiency: 32%-84% Pump weight: 78-3750kg Motor power: 3-1120kw NPSH: 2.0-7.0m Price: 0.79-168,000

Products Details

The material of the main parts of the pump: Inlet and outlet section: ZG230-450 Middle section: ZG230-450 Guide vane: QT450 Impeller: QT450 Spindle: 40Cr Sealing ring: QT450 Bushing: HT250 Balance plate: ZG2Cr13 Gimbal: Tin bronze Pump installation steps: 1.1 Preparations 1.1.1 Before assembly, all pump parts, especially the mating finishing surfaces, must be thoroughly cleaned. 1.1.2 Count all the parts, and classify and number the parts according to the assembly order. 1.2 Assembly of pump parts 1.2.1 Pay attention to install the sealing ring in the middle section to prevent it from falling off. 1.2.2 Pay attention to the guide vane anti-rotation pin. 1.2.3 Tighten the nut of the pump body through the rod symmetrically to maintain a proper tightening force. If it is too loose, it will cause leakage of the joint surface of the middle section. If it is too tight, it will cause deformation of the stator parts. Tighten the threaded rod symmetrically. 1.2.4 After the threaded rod is basically tightened, use a dial indicator to find out that the front and rear sections are not parallel. 1.3 Measure the total string volume of the rotor, which should meet the requirements of the drawing. 1.4 Install the front cover and low pressure end cover bearing and lower shoe, and lift the shaft to the center position. 1.5 Use a special lifting tool and a dial gauge to check the runout of the end face of the balance sleeve, which should meet the requirements of the general assembly drawing. 1.6 Assemble the rotor parts and tighten the lock nut. The measured string quantity after the balance plate is installed shall meet the requirements of the general assembly drawing. 1.7 Install the head cover, tail cover, bearing body and the top of the bearing pad and the clearance on both sides, which should meet the specified value of the bearing pad quality requirements. 1.8 Adjust the center of the bearing bush on both sides, and lock the adjusting nut after adjustment. 1.9 Assembling the thrust bearing 1.9.1 For the assembly of the thrust bearing components, scrape and grind the black pads according to the requirements of the bearing components, and the thrust pads should rotate flexibly during assembly. 1.9.2 After the thrust bearing is installed, the axial gap between the balance disc and the balance sleeve should be 0.04~0.08mm according to the requirements of the general assembly drawing, and the adjustment of the gap is realized by the adjusting ring. 1.9.3 After adjusting the clearance, install the thrust bearing and thrust plate, and lock the lock nut. The pump body and the pump cover constitute the working chamber of the impeller. The inlet and outlet flanges are provided with pipe screw holes for installing vacuum gauges and pressure gauges, and the lower part of the pump body is provided with pipe screw holes for discharging residual water. The impeller is single-suction closed type. A balance disc is set to balance most of the axial force. At the same time, a thrust bearing is provided to bear a small part of the axial thrust that may remain. The arrangement of the bearing keeps the shaft in a stable pulling rod state. The impeller must be strictly checked for static balance before assembly to ensure smooth operation. The pump shaft is supported by two babbitt alloy sliding bearings, which are installed in the bearing body in the pump suspension and lubricated with thin oil. There is a sealing ring on the pump body, which can improve the volumetric efficiency of the pump. On the other hand, it can also prevent high-pressure water from flowing back into the suction chamber, disturbing the water inlet flow field, and ensuring the suction performance of the pump. The shaft seal is generally a soft packing seal. When the pump is working, a small amount of medium can be introduced to the stuffing box, and cooling and lubricating water can also be externally connected to play the role of water seal and cooling and lubrication. According to the user's needs, the packing seal can be changed to a mechanical seal. 1.9.4 Adjust the clearance between the thrust bearing seat and the push plate by the cushion to ensure the clearance requirements of the thrust bearing in the assembly drawing.

The material of the main parts of the pump: Inlet and outlet section: ZG230-450 Middle section: ZG230-450 Guide vane: QT450 Impeller: QT450 Spindle: 40Cr Sealing ring: QT450 Bushing: HT250 Balance plate: ZG2Cr13 Gimbal: Tin bronze Pump installation steps: 1.1 Preparations 1.1.1 Before assembly, all pump parts, especially the mating finishing surfaces, must be thoroughly cleaned. 1.1.2 Count all the parts, and classify and number the parts according to the assembly order. 1.2 Assembly of pump parts 1.2.1 Pay attention to install the sealing ring in the middle section to prevent it from falling off. 1.2.2 Pay attention to the guide vane anti-rotation pin. 1.2.3 Tighten the nut of the pump body through the rod symmetrically to maintain a proper tightening force. If it is too loose, it will cause leakage of the joint surface of the middle section. If it is too tight, it will cause deformation of the stator parts. Tighten the threaded rod symmetrically. 1.2.4 After the threaded rod is basically tightened, use a dial indicator to find out that the front and rear sections are not parallel. 1.3 Measure the total string volume of the rotor, which should meet the requirements of the drawing. 1.4 Install the front cover and low pressure end cover bearing and lower shoe, and lift the shaft to the center position. 1.5 Use a special lifting tool and a dial gauge to check the runout of the end face of the balance sleeve, which should meet the requirements of the general assembly drawing. 1.6 Assemble the rotor parts and tighten the lock nut. The measured string quantity after the balance plate is installed shall meet the requirements of the general assembly drawing. 1.7 Install the head cover, tail cover, bearing body and the top of the bearing pad and the clearance on both sides, which should meet the specified value of the bearing pad quality requirements. 1.8 Adjust the center of the bearing bush on both sides, and lock the adjusting nut after adjustment. 1.9 Assembling the thrust bearing 1.9.1 For the assembly of the thrust bearing components, scrape and grind the black pads according to the requirements of the bearing components, and the thrust pads should rotate flexibly during assembly. 1.9.2 After the thrust bearing is installed, the axial gap between the balance disc and the balance sleeve should be 0.04~0.08mm according to the requirements of the general assembly drawing, and the adjustment of the gap is realized by the adjusting ring. 1.9.3 After adjusting the clearance, install the thrust bearing and thrust plate, and lock the lock nut. The pump body and the pump cover constitute the working chamber of the impeller. The inlet and outlet flanges are provided with pipe screw holes for installing vacuum gauges and pressure gauges, and the lower part of the pump body is provided with pipe screw holes for discharging residual water. The impeller is single-suction closed type. A balance disc is set to balance most of the axial force. At the same time, a thrust bearing is provided to bear a small part of the axial thrust that may remain. The arrangement of the bearing keeps the shaft in a stable pulling rod state. The impeller must be strictly checked for static balance before assembly to ensure smooth operation. The pump shaft is supported by two babbitt alloy sliding bearings, which are installed in the bearing body in the pump suspension and lubricated with thin oil. There is a sealing ring on the pump body, which can improve the volumetric efficiency of the pump. On the other hand, it can also prevent high-pressure water from flowing back into the suction chamber, disturbing the water inlet flow field, and ensuring the suction performance of the pump. The shaft seal is generally a soft packing seal. When the pump is working, a small amount of medium can be introduced to the stuffing box, and cooling and lubricating water can also be externally connected to play the role of water seal and cooling and lubrication. According to the user's needs, the packing seal can be changed to a mechanical seal. 1.9.4 Adjust the clearance between the thrust bearing seat and the push plate by the cushion to ensure the clearance requirements of the thrust bearing in the assembly drawing. Featured Products

-

ISWH type horizontal explosion-proof stainless steel pipeline pump

-

ZJQ wear-resistant submersible slurry pump

-

DL type vertical multistage pump

-

IS horizontal single-stage single-suction centrifugal pump

-

SH type single-stage double-suction split pump

-

DG type multi-stage boiler feed pump

-

HYB constant pressure variable frequency water supply equipment

-

MD type mining wear-resistant multistage centrifugal pump

-

ISW type horizontal pipeline centrifugal pump

-

Quality HYB Constant Pressure Water Supply Equipment Direct From Factory

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours